The first Sunscreen Simulator was developed and made available on the Internet by Ciba Specialty Chemicals in 2002. In the meantime, it has been improved by BASF 2011, and since 2017 we also have the DSM Sunscreen Optimizer on the Internet. Does this mean that we have an artificial intelligence (AI) solution to predict sunscreen performance? Although there is now quite a hype about AI, I would not call it that. Sunscreen simulators are conventional bottom up calculations based on physics and a model of the sunscreen film on the skin, calibrated with a few dozen data points of well-known SPF value. Although such calculations are very useful, these calculations have not much to do with what we generally understand under AI.

How would then an AI approach look like? In a “real AI” solution there would be a data base containing the characteristics of hundreds or thousands of sunscreens that would serve to teach

the AI system to predict sunscreen performance. It would actually be quite an effort to establish such a database and it is questionable if all relevant sunscreens could be included in such a scheme at all. Another question would be how well all these sunscreens could be characterized to make them useful for the database. Furthermore, in the case of AI, the gigo-rule also applies (garbage in, garbage out).

So, I do not think AI will design sunscreens any time soon … but the bottom up, model-based sunscreen simulations have been helping formulators worldwide for the last 20 years. In this column I will discuss a recent example of the use of a sunscreen simulator by an experienced formulator, Dr. Christiane Hanay from SkinXpert, which has been published in the series of papers Challenges in Sun Protection 1. The sunscreen simulator has also generally been used to explain how sunscreens work and helped debunking certain myths, such as SPF is only UVB protection or that there is an exponential relationship between SPF and amount sunscreen applied (whereas it is mostly linear) 2.

Let us first check what the hyped AI tool Chat GPT (generative pre-trained Transformer) has to say about sunscreen simulation tools to predict the SPF (Table 1). The answer confirms, that the in-silico tools are well known, and also strengths and limitations are covered by the Chat GPT answer. So, as one of the developers and expert on in-silico tools I am very pleased with this answer. I could not have said it better.

| QUERY: Do you know the BASF sunscreen simulator and the DSM sunscreen optimizer? How do they work and how accurate can they predict the SPF of a sunscreen? Yes, I‘m familiar with both the BASF Sunscreen Simulator and the DSM Sunscreen Optimizer. These are widely used computer-based tools developed by BASF and DSM, respectively, to predict the sun protection factor (SPF) of sunscreen formulations. Here‘s a brief overview of how they work and their accuracy: 1. BASF Sunscreen Simulator: The BASF Sunscreen Simulator is a comprehensive tool that utilizes mathematical models based on the absorption and scattering properties of sunscreen ingredients. It takes into account various factors such as the spectral distribution of UV radiation, the concentration and characteristics of UV filters, and the effects of formulation components like emollients and thickeners. The simulator calculates the SPF by simulating the interactions between UV radiation and the sunscreen formulation. It can also provide information on critical wavelength, UVA protection, and photostability. BASF has extensively validated the Sunscreen Simulator against experimental measurements and real-world data. While the tool provides a good estimation of SPF, its accuracy may vary depending on the specific sunscreen formulation and the availability of accurate input data. 2. DSM Sunscreen Optimizer: The DSM Sunscreen Optimizer is another widely used tool that helps in formulating sunscreens with desired SPF values. It employs a combination of mathematical modeling, statistical analysis, and optimization algorithms to predict and optimize the SPF of sunscreen formulations. The tool considers various formulation parameters, such as the type and concentration of UV filters, the emollient system, and the formulation viscosity. The DSM Sunscreen Optimizer has been developed using extensive experimental data and has undergone validation against real-world SPF measurements. It aims to provide accurate predictions of SPF, but the accuracy can still be influenced by the quality of input data and the complexity of the formulation. Both the BASF Sunscreen Simulator and the DSM Sunscreen Optimizer have been widely used in the cosmetic industry and have proven to be valuable tools for sunscreen formulation development. However, it’s important to note that accurate SPF prediction depends on the accuracy of the input data and the underlying models used by these tools. Real-world testing and validation are still necessary to ensure the reliability of SPF predictions and to account for individual variations in sunscreen performance. |

However, this is not so surprising, is it. After all, an AI tool is trained by what is available on the Internet and therefore reflects, probably to a great part, the opinion of my ex-colleagues at Ciba SC, BASF and DSM and myself. By the way, Chat GPT does not give you any references; it politely asks you to do your own literature research:

To find publicly available titles and abstracts of scientific literature regarding SPF simulation programs, I recommend using academic search engines or databases such as PubMed, IEEE Xplore, or Google Scholar. These platforms provide access to a wide range of scientific articles and publications. By searching for keywords such as “SPF simulation programs” or “sunscreen formulation simulation,” you should be able to find relevant research papers and abstracts on the topic.

In the reference list you find the links to the sunscreen simulator from BASF3 and the Sunscreen Optimizer from DSM-Firmenich4. If you want to dig deeper into the development of SPF simulation programs, I recommend O’Neill 19845, where it all started, the work of Ferrero et al 20036 and a review of the state of the art by Herzog und Osterwalder 20157.

So, let us come to the example of sunscreen development with the help of the in-silico tool. You find the whole article Challenges in Formulating Sunscreens by Hanay and Osterwalder in1.

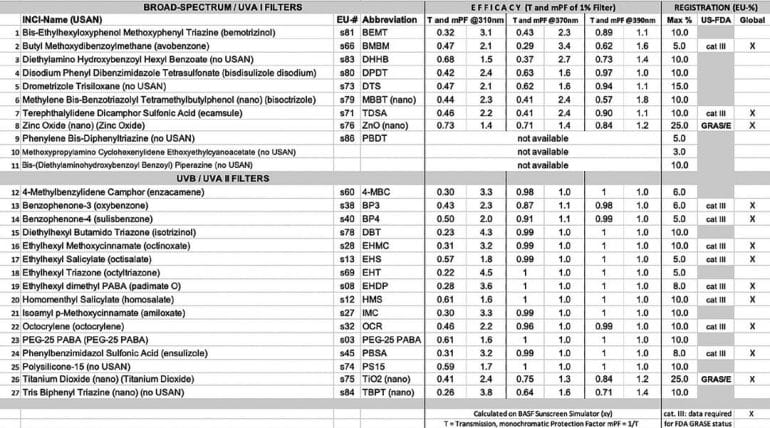

Both BASF Sunscreen Simulator and DSM Sunscreen Optimizer3,4 are very useful in silico calculation tools for determining UV protection profiles and the performance metrics, such as SPF, UVA-PF, and UVA Ratio. The calculation is based on the properties and concentration of the UV filters, given in Table 2, and on a model of the irregular sunscreen film on the skin first described by O’Neill5.

Spectral Absorption Optimization:

UV Filter Platform Selection

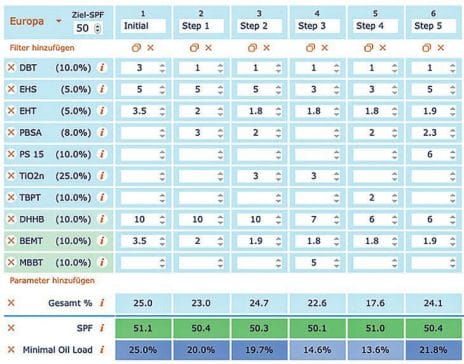

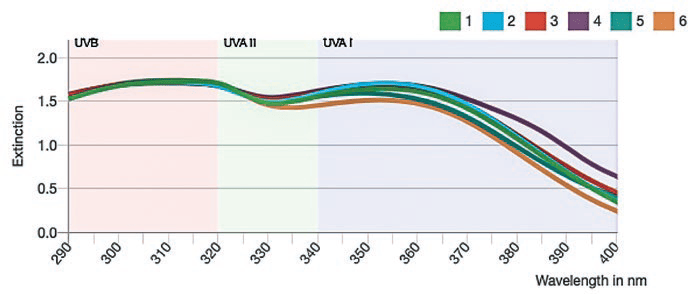

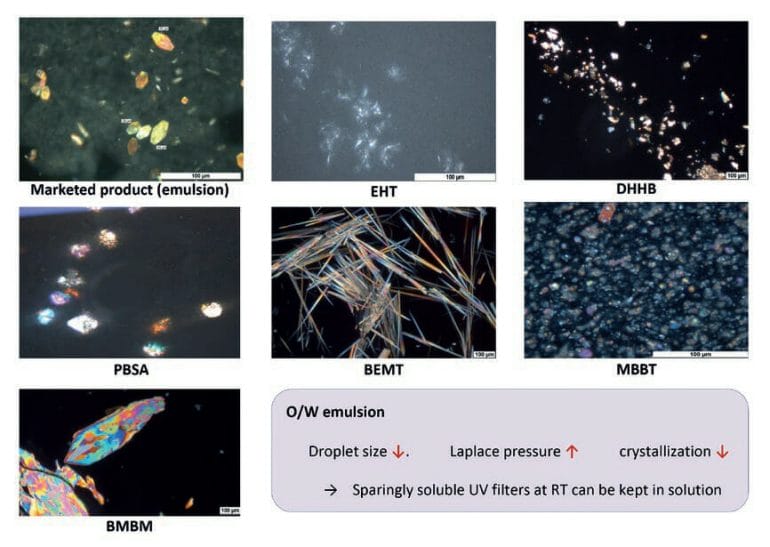

Figure 1 (column 1 “Initial”) describes a first attempt to achieve an SPF 50 in silico with “the remaining five” UV filters, all of which are approved in Europe8 and are currently under critical discussion. By combining “the remaining five” UV filters, DBT, EHS, EHT, DHHB, and BEMT, it is theoretically possible to achieve an SPF 50 and a UVA-PF of at least one-third of the SPF with a total UV filter of 25% and good UV filter efficiency (SPF/%UV filter = 2). Broad-spectrum protection close to spectral homeostasis is theoretically feasible. However, experience has shown that it is a major challenge to dissolve the required UV filter concentrations. Total use concentrations above 6% of the poorly soluble triazines BEMT, DBT and EHT run the risk of recrystallizing in normal emulsions. In addition, the use of DHHB at the maximum limit of 10% can lead to other side effects with certain oil components, such as discoloration of the fingernails (another performance concern from consumers). This example shows that in the very high UVB-UVA protection range, not all so called “free from” wishes can be accommodated. Recrystallization of the crystalline UV filters is a major risk in formulation and must be avoided at all costs. Crystalline UV filters must be kept in solution throughout the life cycle of the product, as recrystallization will result in a lower protection factor, a reduction in product stability, and a deterioration in the appearance of the product. Figure 2 shows a collection of the typical crystal shapes by polarized light microscopy of crystalline UV filters in selected sunscreen emulsions.

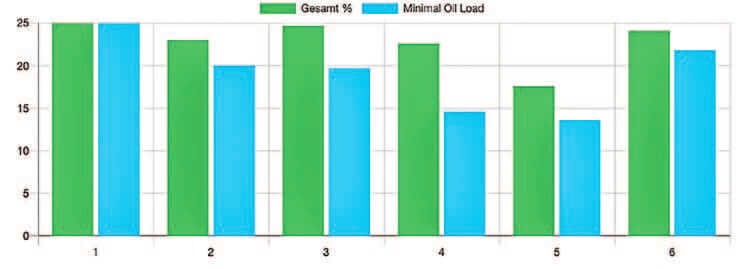

Starting with the initial, poorly soluble, composition the tool leads through 5 optimization steps. Then comes DECISISON TIME, e.g., by omitting only one of the “free from” claims in favor of technical and performance arguments, efficiency can be increased significantly (Step 1 to Step 5). Shown are the UV filter concentrations in each formulation, the calculated SPF and the minimal oil concentration required to dissolve these UV filters. Furthermore graphically, the protection spectra, the total UV filter concentration and the minimal oil load for each formulation.

(www.sunscreensimulator.basf.com or www.sunscreen-optimizer.com).

Within the scope of stability testing, the nucleation/ crystal growth of crystalline UV filters is recorded in real time by means of polarization microscopy at different storage temperatures. Tracking of recrystallization as a function of temperature and storage time is necessary over the whole process. In the case of an O/W emulsion, the critical crystallization temperature is pressure dependent. As droplet size decreases, the Laplace pressure in the droplet increases, so recrystallization is strongly hindered. UV filters, which are sparingly soluble at room temperature, can be kept in solution longer in O/W emulsions by this effect. However, after some time and at certain UV filter concentrations, this positive effect decreases.

Efficiency Maximization: Decision Time

In order to maximize the efficiency of the UV filter platform, the previously discussed poorly soluble UV filter combination of “the remaining five” can be optimized by adding further UV filters in such a way that (1) experience shows better solubility and (2) a target SPF of 50+ can be achieved with the lowest possible total filter concentration. An in silico sunscreen simulation tool was used as a helpful tool prior to practical development in the laboratory (Figure 1).

Avoiding recrystallization of crystalline UV filters in sunscreen products is key to avoid loss of protection, stability, and/or appearance. Shown are 1 commercial product and 6 standard sunscreen formulations containing a single UV filter expressing crystallization.

Step 1: Three percent PBSA was added as a water-soluble UVB filter. This already ensures that the required concentration of all poorly soluble crystalline triazine derivatives BEMT, EHT, and DBT can be reduced to concentrations that are readily soluble in the formulation. This reduces the total filter concentration while increasing the UV filter efficiency, allowing this UV filter combination to be used in real-world applications.

Step 2: PBSA was reduced to 2%, and an additional 3% TiO2 was used instead. This reduces the efficiency to the initial level, but the poorly soluble UV filters BEMT and EHT could be reduced even further. The use of titanium dioxide legally requires the nano declaration, leading to downgrading by consumer apps.

Step 3: Instead of PBSA, the particulate organic UV filter MBBT was used together with titanium dioxide, both with the nano declaration. With the same SPF, the DHHB concentration was reduced, and the UV filter efficiency was increased. Also, the UVA-PF and the absorption in UVA I could be increased, which is very beneficial. However, due to the high pigment concentration of 5% MBBT and 3% TiO2, this formulation will cause whitening on the skin, which is undesirable in terms of application comfort and leads to a poor consumer rating.

Step 4: MBBT was replaced by the newer pigmentary, very efficient UVB/A-II filter TBPT (nano) and again combined with PBSA. The total filter concentration was significantly reduced. The UV filter efficiency is now almost 3. Very importantly, this combination does not leave a disturbing whitening effect on the skin.

Step 5: Instead of the pigmentary UV filters, the UVB filter PS-15 was used. This combination is the best in terms of performance and non-sticky skin feeling. It is not nano, but not silicone-free and also not quite low cost. Therefore, this combination is an option for products that require higher performance. The UV filter efficiency is in the same range as the UV filter combination at the start. The UVA-PF in relation to the SPF is at the lower limit with just one-third of the SPF.

In conclusion, a significant increase in UV filter efficiency is possible by omitting only one of the “free from” claims such as non nano or silicone free, in favor of technical and performance arguments, which creates room for additional ingredients in the sunscreen formulation.

I hope those who already know and use sunscreen simulation tools find this example useful, and that I can encourage those who do not yet know them, to try them out and design their sunscreen on the computer.

References

- Hanay C, Osterwalder U. Challenges in Formulating Sunscreen Products. Curr Probl Dermatol. 2021;55:93-111. doi: 10.1159/000517655. Epub 2021 Oct 25. PMID: 34698033.

- Osterwalder U, Sohn M and Herzog B, Global State of Sunscreen, Photodermatology, Photoimmunology & Photomedicine, 30: 62-80 2014 BASF Sunscreen Simulator. Available from: https://www.sunscreensimulator.basf.com/Sunscreen_Simulator/login, accessed March 2020.

- DSM Sunscreen Optimizer. Available from: https://www.sunscreen-optimizer.com/index.html, accessed September 09, 2020.

- O´Neil JJ, Effect of Film Irregularities on Sunscreen Efficacy, J Pharm Sci, 73(7), July 1984

- Ferrero L, Pissavini M, Marguerie S, Zastrow L. Efficiency of a continuous height distribution model of sunscreen film geometry to predict a realistic sun protection factor. J Cosmet Sci. 2003 Sep-Oct;54(5):463-81.

- Herzog B and Osterwalder U, Simulation of Sunscreen Performance, Pure Appl. Chem. 2015

- Regulation (EC) No 1223/2009. List of UV filters allowed in cosmetic products, Annex VI. Available from: https://eurlex. europa.eu/legal-content/EN/TXT/PDF/?uri=

Uli Osterwalder

Uli Osterwalder studied Chemical Engineering at ETH Zurich, Switzerland and at the University of Houston in Houston, Texas. He joined Ciba-Geigy in Basel in 1979 where he first developed a Phosgene Generator in central process development. Later he developed his leadership skills in Project Management and Process Analytics. At Ciba Specialty Chemicals Uli Osterwalder helped establish new business development in Fabric Care and Personal Care. After the acquisition by BASF SE he became Senior Marketing Manager and Scientific Adviser in Sun Care in Ludwigshafen and Duesseldorf.

2016 he came back to Basel, working for DSM as senior Senior Scientific Adviser suncare for two years. 2018 he started his own company, Sun Protection Facilitator GmbH and is committed to contribute to further improvements in sun protection. Uli Osterwalder works for ISO on the development of new UV protection assessment methods and is now chairing the technical committee ISO TC/217 (Cosmetics). He is author and co-author of numerous scientific articles and book chapters on sun protection.