A conversation with Alexander Selig, Chemical Engineer and Global Head of Application Service Consumer Care, CHT Germany GmbH

EURO COSMETICS: Silicones are currently not the first choice in the Personal Care Industry in respect of sustainability and actual trends. How do you approach this challenge?

Alexander Selig: Sustainability is one of the biggest challenges for the cosmetics industry. Consumers expect the best of both worlds: high quality and top performance on one side and sustainable use of resources on the other side. The current way is to use as many ingredients as possible from natural sources to cover the sustainability expectation. The consequences are a loss in performance, which opens a new topic regarding water footprint, deforestation and all the risks that industrial farming brings. The future for product development requires a deep understanding of the interaction of ingredients, packaging and production energy. Synthetic ingredients will play an important role here, as – depending on the type of polymer – they bring various advantages, e.g. they don’t interfere with the food industry and often require only a little amount of silicones to gain good performance and secure a good water footprint. In this context circular economy is also an important topic regarding the use of synthetic ingredients. All in all, the future will be a mix of synthetic and natural ingredients, resulting in a slimmer formulation.

EURO COSMETICS: Do you have examples how silicones can help to reduce the amount of ingredients in formulations?

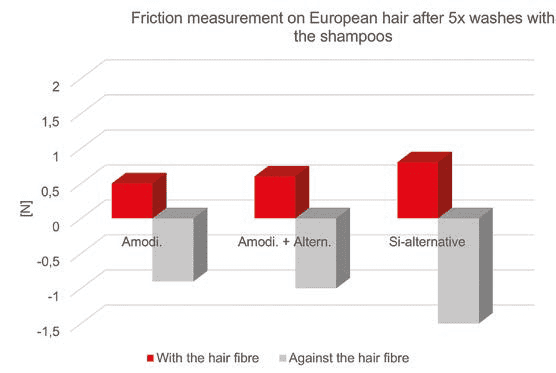

Alexander Selig: A nice example is the combination of silicones and silicone alternatives in hair care products. A lot of companies try to imitate the performance of silicones – with more or less success. There is a significant difference regarding the silicone and non-silicone chemistry which makes it very difficult to gain the same properties, especially in hair care. Therefore CHT started a performance assessment trial to study the possibilities and results of combining the two ingredients:

A classic SELS based shampoo was prepared with

a)2.0% of CHT-BeauSil AMO 815 EM a30% Amodimethicone emulsion

b)0.5% of CHT-BeauSil AMO 815 EM and0.5% w/w of PCA-Glyceryl Oleat

c)1.0 % of PCA-Glyceryl Oleat a 100% Silicone Alternative from natural source (Table 1).

| Shampoo with 2% of AMO 815 | Shampoo with 0.5% of AMO 815 and PCA-Glyceryl oleat | Shampoo with 1.0% of PCA-Glyceryl oleat | |

| Total amount of conditioning agent in the shampoo: | 0.6% synthetic | 0.15% synthetic + 0.5% natural | 1.0% natural |

The result was, that the combination of the two products has shown a performance of 2.0% silicone emulsion and a better performance as the 1.0% of the silicone alternative. This is clear proof that it is possible to use less ingredients and still have an excellent performance. (Figure 1)

EURO COSMETICS: Are there additional options to improve the sustainability footprint of silicones in hair care?

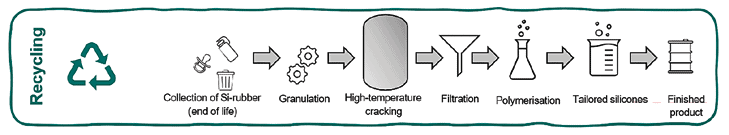

Alexander Selig: Silicone is a versatile material that finds use in a wide range of different applications and as such its commercial importance is significant. Silicones are an integral part of additives in consumer care products, e.g. personal care. However, the production of silicones is extremely energy-intensive. To fully exploit the value of this resource, end-of-life silicone products can be recycled. As a result, today’s silicone waste can be used to produce an important alternative raw material for tomorrow. This approach to silicone recycling follows the waste-to-value process and takes place across several stages. The end-of-life polymers are catalytically split into silicone monomers, then modified, and then finally polymerized into e.g. a new modified silicone in virgin quality, which can be used for personal care products. (Figure 2)

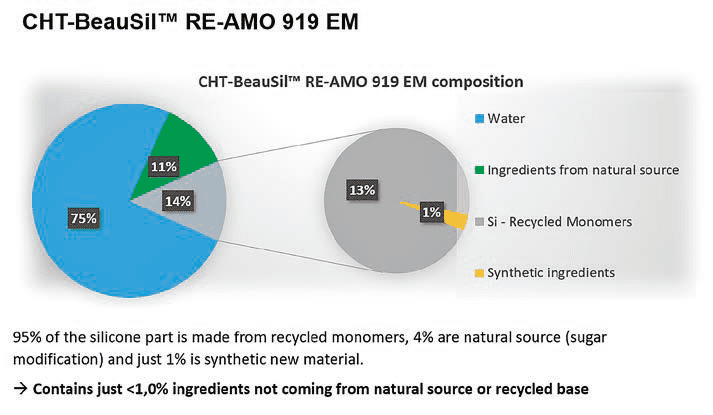

Based on this concept, CHT has de-veloped CHT-BeauSil RE-AMO 919 EM (Gluconamido Amodimethicone (and) Coco glucoside), the first recycled and sugar modified silicone for hair care. With this product a new option is born for formulators to use claims like “based on recycled polymer technology”. Addi-tionally, the sugar modification of the silicone polymer allows unique effects on the hair without the heaviness of classic Dimethiconols. (Figure 3)

The CHT-BeauSil RE-AMO 919 EM is a micro emulsion stabilized with sugar surfactant (APG). The silicone polymer itself is made of recycled silicones and modified in the final stage with sugar. Due to this unique combination the product has an excellent footprint. (Figure 4)

EURO COSMETICS: These concepts are all related to hair care. Are there any examples which would also work for skin care?

Alexander Selig: The question whether silicones are a good and sustainable choice for skin care products can be easily answered by a counter question. Why does the pharma industry use silicones in their cremes and gels? It is a proven fact, that silicones have a high breathability, a great skin feeling and – most importantly – do not cause allergy reactions. However, in the interest of decreasing ingredients, CHT has developed a concept combining both synthetics silicones and alternatives also for skin care products: CHT-BeauSil GEL 8187 EM (Dimethicone (and) Polysilicone-11 (and) Decyl glucoside (and) Butylene Glycol) is a concentrated Silicone-Gel and perfect for low concentrated formulations like facial masks, facial tonics, paper masks and other formulas. The additional advantage is that this product doesn’t require high shear, like it is necessary for other silicone gels, and thereby significantly contributes to saving energy. The CHT-BeauSil GEL 8187 EM can be added easily to the water phase as it is ready dispersible and even possible to help to solubilize small amounts of other lipids. All in all it is a 5 in 1 solution like a “Swiss knife”. The CHT-BeauSil GEL 8187 EM is emollient, reduces tackiness, supports hydration, masks wrinkles Wrinkle masking, is solubilizing.

As an example a facial paper mask formulation with the solubilizing properties of CHT-BeauSil GEL 8187 EM (Figure 5–7)

Strong hydration booster

Sensory advantage

of CHT-BeauSil GEL 8187 EM

Using just 2% of CHT-BeauSil GEL 8187 EM great effects can already be achieved. By avoiding classic petrochemistry-based surfactants the product gets an additional sustainable touch by using sugar surfactant.

EURO COSMETICS: How do CHT and Biesterfeld work together in promoting sustainable personal care products?

Alexander Selig: The role of an experienced and reliable distribution partner is of great important to the success of promoting more sustainability in our industry. The closer the cooperation and the better the expertise of both partners complement each other, the more successful the project will be. Biesterfeld Spezialchemie is our partner of choice and it shows that we work together very successfully as a team. With their expertise in the distribution of sustainable personal care products, excellent pan-European network and a broad range of industry specific certificates, quality seals and regular audits, we are growing closer together with each passing year. But, most importantly, Biesterfeld and CHT share the same values and principles which is key for our joint effort.

Biesterfeld’s technical advice, their approach to innovation, their marketing and sales expertise, and, above all, their extensive experience and support service regarding sustainable product development make us a strong team in this joint effort. For example, we have been working together in the Biesterfeld Lab and Innovations centre for some time now, testing and developing sustainable product solutions. This is by no means possible with every distribution partner and is a very important success factor for our cooperation.

We on the other hand have set the course for an ambitious yet sustainable growth policy with our new “Corporate Strategy 2025”,. E.g., the CHT Group has been a signatory of the UN Global Compact since mid-2016 and is therefore committed to the 10 principles of the United Nations Global Compact and to responsible corporate governance with integrity.In many areas, such as supplier evaluation, optimal raw material selection, innovative product development, corporate social responsibility, or resource saving processes, we focus on promoting sustainability where we can.

EURO COSMETICS: Thank you for the conversation.

Infobox “sustainable production”

The main silicone production plant in Germany, Oyten, close to Bremen source the energy for generating heat for the reactors from biogas. The biggest production plant of CHT, Dußlingen in Germany has a 700m² photo-voltaic plant to generate electrical power for the plant.

CHT Group is a foundation-based company with a high value on sustainability targets in the foundation set up. CHT is part of Ecovadis with a silver status (2021).

The CHT Group is a medium-sized global player for specialty chemicals and active worldwide in development, production and sales. CHT Germany GmbH in Tübingen is the headquarters of the group of companies which focuses on sustainable chemical products and process solutions. TEXTILE SOLUTIONS of CHT improve the quality, functionality as well as look and purity of textiles and optimize their manufacturing processes. In the fields of silicones, building materials, paints, coatings, paper, agrochemicals as well as cleaning and care products innovative products and process solutions are provided by INDUSTRY SOLUTIONS. By combining the strengths of the complete group further innovative products, applications or processes are continually developed and vast technical support is offered within the SCIENCE & SERVICE SOLUTIONS. Highly qualified specialists work in state-of-the art laboratories for development, analytics and application technique in order to work out ideas and solutions that meet the latest requirements. The CHT Group with its own production and sales locations is represented by more than 26 companies worldwide. In the financial year 2021, the CHT Group generated a group turnover of 630 million Euro with around 2,400 employees.

More information www.cht.com

Biesterfeld Spezialchemie is one of the leading international distributors of specialty chemical products, pharma and food ingredients. The company offers extensive market knowledge and tailor-made, application-based technical advice across a diverse product portfolio focusing on the requirements of selected industries, including composites and tooling, personal care and cleaning, healthcare, paints and coatings, adhesives, polyurethane, construction, nutrition, food supplements, electric, electronic and energy.

Biesterfeld Spezialchemie is a division of the Biesterfeld Group, one of the world’s leading distribution and service companies in the field of plastics, rubber and specialty chemicals. Founded in 1906 in Hamburg, Germany, today the group has more than 1000 employees across 50 locations in Europe, North and South America, Asia and Africa and generates an annual revenue of 1.4 billion EUR (FY 2021). The fully family-owned company operates in the business divisions Biesterfeld Plastic, Biesterfeld Spezialchemie and Biesterfeld Performance Rubber.

ore information www.biesterfeld.com