A conversation with Dr. Bernhard Fellenberg, state-certified food chemist at the BAV Institute

Introduction:

Water is the most important and most frequently used raw material in the manufacture of cosmetic products. Water is not only used as a formulation component but also for cleaning purposes. Safe microbiological quality is therefore of central importance for bringing safe cosmetics onto the market.The following FAQs on the subject of microbiological requirements for water in cosmetics companies are intended to provide answers to important questions on this subject.

“In order to avoid a potential risk to the product or the health of the product user, it is essential that the water used is of sufficient microbiological quality”

EURO COSMETICS:

Why does the microbiological quality of water play such an important role?

Dr. Bernhard Fellenberg:

As already mentioned at the beginning, water is used as the largest component in many cosmetic products. Under certain conditions, undesirable microorganisms may be present in the water or the water itself may serve to enrich these microorganisms. In order to avoid a potential risk to the product or the health of the product user, it is essential that the water used is of sufficient microbiological quality.

EURO COSMETICS:

Are there legal requirements for microbiological water quality?

Dr. Bernhard Fellenberg:

In contrast to chemical impurities, there are no legally defined specifications for microbiology, e.g. in the EU Cosmetics Regulation [1]. However, there are several guidelines and recommendations that deal with maximum levels of certain microorganisms. The most important guideline is the standard DIN EN ISO 17516 [2], which deals with the definition of microbiological limit values for cosmetics. Even though this standard specifies requirements for end products, the cosmetics GMP in accordance with DIN EN ISO 22716 [3] also requires that all raw materials used – including the water used – fulfil the quality requirements for finished cosmetic products (including the microbiological specifications).

EURO COSMETICS:

What are the exact limits and recommendations for the different waters?

Dr. Bernhard Fellenberg:

Due to high quality characteristics and continuous quality testing, it should be assumed that both mineral and table water as well as drinking water are generally suitable for the production of cosmetics with regard to their original quality. Nevertheless, it is advisable to treat water, regardless of its formal quality, by means of internal treatment steps to ensure that it is of a consistent and sufficient quality that complies with the EU Cosmetics Regulation. The following is an overview of microbiological quality requirements for various waters[4]:

| Reference | Germ | Limits |

| Drinking water Regulation | Total germ count Escherichia coli Coliform bacteria Enterococci Pseudomonas aeruginosa | 100 CFU/ml 0 CFU/100 ml / 0 CFU/250 ml 1 0 CFU/100 ml / 0 CFU/250 ml 1 0 CFU/100 ml / 0 CFU/250 ml 1 0 CFU/250 ml 1 1 limit value for delivery in sealed containers |

| Mineral water/ Table- water Regulation | Escherichia coli Coliform bacteria Enterococci Pseudomonas aeruginosa | 0 CFU/250 ml 0 CFU/250 ml 0 CFU/250 ml 0 CFU/250 ml |

| Process water (Production, Plant cleaning) according to DGK | Total germ count | 100 CFU/ml * Target value: < 10 CFU/ml |

Finally, it is up to the cosmetics manufacturer to make a risk-based determination of the water quality. This may result in values that deviate from the above specification or are stricter.

EURO COSMETICS:

What are the essential elements for the operation of a water system?

Dr. Bernhard Fellenberg:

In general, cosmetics GMP requires controlled process management to achieve the previously defined and specified water qualities. Technical expertise is essential for the planning and operation of a water system, all components must be checked regularly and the systems must be designed in such a way that they take the local conditions into account. Central components of such a mostly complex water system can be

- Ring main systems with the aim of avoiding standing water

- Membrane filtration

- Ultrafiltration

- Reverse osmosis

- UV radiation

- Ozonisation

- Suitable sampling points

EURO COSMETICS:

What faults can occur in a water system?

Dr. Bernhard Fellenberg:

Faults in the water system that are not detected can lead to permanent and continuous contamination of the water and therefore also of the final cosmetic product. The following are examples of possible faults:

- Coarse filter clogged and/or torn (during pre-treatment)

- Membrane filter clogged and/or torn (during sterilisation step)

- Circulation not correct, dead legs and dead pipes (with circulation)

To avoid such errors, regular inspection rounds should be used to visually inspect the system (e.g. tightness) and other system-specific parameters (e.g. volume flows, conductivity). Here too, it is important to recognise possible faults at an early stage through regular inspections in order to prevent extensive product contamination.

EURO COSMETICS:

How often should I test the water?

Dr. Bernhard Fellenberg: Unlike many other raw materials, the water used for production is not subject to a pre-release process, but is always used directly in the process. The microbiological quality must therefore be checked continuously, also so that countermeasures can be taken immediately in the event of deviations. Ideally, the water should be tested weekly. It is important that not only one sample is analysed, but that several samples are systematically examined throughout the entire water system. Appropriate documentation of testing times and locations is part of a comprehensive quality management system.

EURO COSMETICS:

How must the sample be taken?

Dr. Bernhard Fellenberg:

Aseptic sampling is essential due to the fact that microorganisms can get into the water if the sample is not taken correctly and these can multiply quickly (there are no preservative substances present). With regard to the sampling technique, the Drinking Water Ordinance can be used as a guide [5]. When taking a sample, the valve or sampling tap must be disinfected beforehand. A certain volume should then be drained first in order to remove any residual water from the pipe. The sample itself must then be quickly filled into a sterile sampling container; in the case of water with chlorine, the reagent thiosulphate should be added to the container in advance for neutralisation.

In individual cases, the water can also be tested directly without prior drainage. This is the case, for example, if it is necessary to check whether bacteria are spreading in the sampling tap.

EURO COSMETICS:

Which microorganisms prefer to grow in water?

Dr. Bernhard Fellenberg:

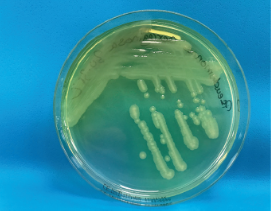

The water mainly contains gram-negative bacteria such as pseudomonads (best known representative: Pseudomonas aeruginosa). However, other gram-negative germs such as Burkholderia cepacia or Pluralibacter gergoviae also play a role.

What they all have in common is that they are able to grow even with a low nutrient supply. The EU’s European rapid alert system, Safety Gate [6], also frequently recalls products that are contaminated with the above-mentioned microorganisms. Other microorganisms such as gram-positive bacteria, yeasts and moulds only play a very minor role.

It should also be mentioned that the microorganisms mentioned are able to form a so-called biofilm. These biofilms form primarily when stagnant water (stagnation) is present. However, other factors such as unevenness or unsuitable materials can also contribute to biofilm formation. In general, biofilms are very difficult to remove and their formation should be avoided by taking appropriate measures and structural design.

Note: The FAQs compiled here are essentially based on the DGK’s technical article on “Microbiological requirements for water used in cosmetics production” [4].

[1] Regulation (EC) No 1223/2009 of the European Parliament and of the Council of 30 November 2009 on cosmetic products, current version

[2] DIN EN ISO 17516:2014 Cosmetics – Microbiology – Microbiological limits

[3] DIN EN ISO 22716:2008 Cosmetics – Good manufacturing practice (GMP) – Guide to good manufacturing practice

[4] Microbiological requirements for water used in cosmetics production, Eigener et. al, DGK 12/2023, www.dgk-ev.de

[5] TrinkwV: Ordinance on the Quality of Water for Human Consumption (Drinking Water Ordinance – TrinkW), current version

[6] Safety Gate: the EU rapid alert system for dangerous non-food products, https://ec.europa.eu/safety-gate

EURO COSMETICS: Thank you for the conversation.